Search our Knowledge Base

- All

- Announcements

- Custom Manufacturing

- Downloadable Resources

- Finishing

- Laser Welding

- Precision CNC Machining

- Precision Sheet Metal Fabrication

- Tube Laser Cutting

What is 5-Axis CNC Machining?

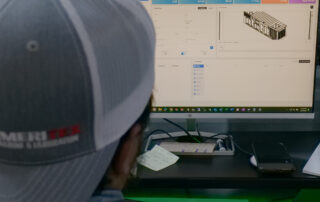

The Power of 5-Axis CNC Machining: Precision & Efficiency at Ameritex Machine & Fabrication In the world of precision metal fabrication, manufacturers constantly seek ways to improve accuracy, reduce costs, and increase efficiency. One of the most significant advancements in modern manufacturing is 5-axis CNC machining. Unlike traditional 3-axis machining, which moves along the X, Y, and Z axes, a 5-axis CNC machine adds two rotational movements, allowing for greater flexibility and more complex [...]

Common Manufacturing Metals for Fabrication

Your Guide to Common Manufacturing Metals and How Ameritex Brings Your Ideas to Life At Ameritex Machine & Fabrication, we specialize in bringing innovative ideas to life using a variety of manufacturing metals. Whether you're developing a new product, scaling a business, or simply exploring fabrication possibilities, choosing the right material is critical. That's why our team of experts are here to guide you every step of the way, from initial design to final [...]

Meet the Ameritex Customer Service Team: Making Your Life Easy

Meet the Faces Behind the Experience: How Ameritex Customer Service Team Drives Value At Ameritex Machine & Fabrication, delivering high-quality custom metal parts and precision sheet metal fabrication isn't just about cutting-edge equipment—it's about people. Behind every switchgear enclosure, laser-cut panel, and fabricated frame, there’s a dedicated team ensuring your project is handled with care, precision, and urgency. Ameritex customer service team is your first line of support and strategy, whether you're a procurement [...]

Ameritex: Built on Experience, Driven by Progress

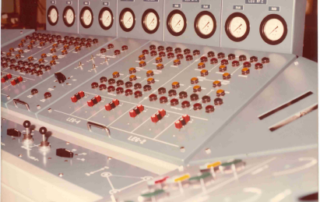

Precision metal parts, sheet metal enclosures, and switchgears. These are more than just products—they're a part of the Ameritex Machine & Fabrication history. A Humble Beginning Before we were Ameritex, we were Cleveland Manufacturing—a small, three-bay shop filled with hardworking individuals who shared a common goal: build quality parts and take care of each other like family. Work Ethic and Family Culture Back in those early days, everything was done by hand. Drawings were handed [...]

Announcing Ameritex’s Innovative New Training Program

Hiring and retaining skilled laborers is harder than ever in manufacturing, with the Manufacturing Institute projecting that there will be 2.1 unfilled positions by 2030. Industry experts say that prioritizing workforce development is key to overcoming this challenge. “Right now, there is a skill divide between the younger and older generation, and it’s up to industry veterans to bridge that gap by upskilling low- and mid-skilled workers to make room for entry-level employees,” writes [...]

Balancing Precision and Cost by Managing Tolerances

Tolerances play a vital role in manufacturing design, defining the allowable variation in a part's dimensions to ensure its functionality. However, balancing precision and managing tolerances can help reduce your manufacturing costs. By specifying tighter tolerances than necessary can significantly drive up production costs. At Ameritex, we help our customers strike the perfect balance between precision and cost-effectiveness. By identifying which dimensions are critical to a part’s function and which are not, we can [...]

Streamlining Operations: The Benefits of Implementing an ERP System

In today’s fast-paced manufacturing landscape, efficiency and precision are critical to success. Businesses across various industries are leveraging Enterprise Resource Planning (ERP) systems to enhance productivity, improve workflow, and streamline operations. But what exactly does ERP implementation entail, what are the benefits of implementing an ERP system, and how can companies successfully integrate these systems into their operations? Understanding ERP Systems ERP systems integrate various business processes—such as finance, procurement, production, supply chain management, [...]

Deburring, how does it work?

Creating high-quality finished products requires more than precise cutting and forming—it also demands careful finishing. In metal fabrication, deburring is the process of removing rough edges and sharp burrs from metal parts. Deburring plays an important yet often underappreciated role in achieving a smooth, safe, and professional finish. At Ameritex, we’ve refined our deburring process to ensure that every part we produce meets the highest standards. Let’s take a closer look at how deburring works [...]

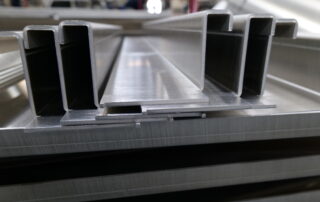

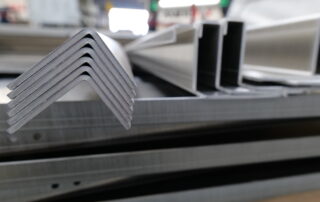

LVD STRIPPIT PX-1530

For high-precision sheet metal fabrication, choosing the right equipment for each job is essential. While fiber lasers are powerful and precise, a punch press offers unique capabilities that can make it the preferred option for certain applications. At Ameritex Machine & Fabrication, our LVD PX-1530 punch press is an integral part of our operation, allowing us to handle complex custom fabrications with speed and accuracy. This post explores the versatility of punch presses and [...]

Understanding K-Factor in Sheet Metal Fabrication

Accurate flat patterns are essential for creating high-quality, reliable sheet metal parts that fit perfectly into your designs. At Ameritex, we understand that the bending process can introduce unique challenges, as the metal compresses on the inside of a bend and stretches on the outside. Without accounting for these changes, parts may not meet your specifications, leading to delays or rework. K-Factor is a critical tool we use to ensure precision in flat pattern [...]