Accurate flat patterns are essential for creating high-quality, reliable sheet metal parts that fit perfectly into your designs. At Ameritex, we understand that the bending process can introduce unique challenges, as the metal compresses on the inside of a bend and stretches on the outside. Without accounting for these changes, parts may not meet your specifications, leading to delays or rework.

K-Factor is a critical tool we use to ensure precision in flat pattern development. By understanding how metal behaves under bending stress, we calculate dimensions with pinpoint accuracy, delivering parts that perform as expected every time. Whether you’re designing for tight tolerances or complex assemblies, the K-Factor plays a key role in getting it right the first time.

K-Factor: Computing the Flat Patter for a Formed Sheet Metal Part

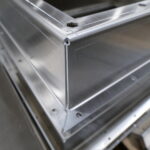

- Bent sheet metal frame using the K-Factor to ensure quality

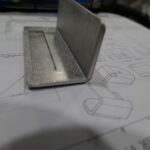

- Lightweight precision: thin sheet metal part with sharp, intricate bends

- Precision-engineered thin sheet metal part with intricate angles, crafted for exceptional accuracy

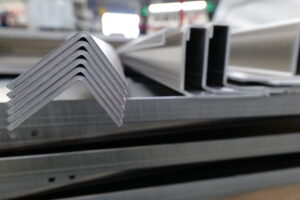

- Perfect precision: A sheet metal bracket bent at a 90-degree angle for superior structural integrity

Creating an accurate flat pattern for a sheet metal fabrication project requires understanding how bending deforms the material. During the bending process, the metal compresses on the inside of the bend and stretches on the outside. As a result, precise calculations are necessary to account for this deformation when determining the flat pattern—the 2D layout of the part before bending.

Simply adding up the body and flange dimensions of a part won’t yield accurate results, as this approach overlooks how the material stretches during bending. That’s where the K-Factor comes in. This mathematical property provides critical insight into how metal behaves under bending stress, enabling the development of precise flat patterns.

What is K-Factor?

The K-Factor is a key element in precision sheet metal fabrication and represents the ratio between the location of the neutral axis and the material thickness. The neutral axis is a theoretical line within the material where there is no tension or compression during bending. This line plays a critical role in determining the accurate length of the metal in its flat form, as the material on this axis does not elongate or compress.

Medium-thickness sheet metal part designed for industrial durability bent at 90 degree angle

In mathematical terms, the K-Factor is a dimensionless value ranging between 0 and 0.5 for most metal fabrication services. This value depends on several factors, including material type, thickness, and the radius of the bend:

• K = 0: This would mean the neutral axis is at the outer surface of the bend, a scenario that’s practically impossible because all materials experience some degree of internal tension and compression.

• K = 0.5: This indicates that the neutral axis is precisely halfway through the material thickness. Although this scenario is also rare, it’s more likely to occur in softer materials or when using larger bend radii.

The formula for calculating the K-factor in sheet metal bending is K = t/MT, where:

K: The K-factor

t: The centerline thickness in the bend

MT: The starting material thickness

For practical applications in custom metal fabrication, K-Factor values generally range from 0.3 to 0.5, depending on specific material characteristics and bending requirements.

The K-Factor in Practice

The K-Factor in Practice

While the theoretical K-Factor offers an initial starting point, material properties and bending equipment introduce variances. To achieve the utmost precision with our flat patterns, at Ameritex we test the theoretical K-Factor through sample bends. To do so, we perform sample bends and measure any discrepancies with the intended dimensions. These tests help us determine the practical K-Factor, which may differ slightly due to material type, thickness, and bending equipment settings. Determining the practical K-Factor is essential for achieving the tightest tolerances, ensuring that each part meets precise specifications for fit and function in complex assemblies.

Once we’ve established the K-Factor for a specific set of parameters—like material thickness, bend angle, and die size—we can apply this value consistently under the same conditions in future projects. However, the calculation methods may vary across different equipment. For instance, our LVD ToolCell press brake utilizes a method known as bend deduction, which can be derived from the K-Factor.

Other machines, like the VaskiPUNCH and Euromac Digibend, used for copper fabrication services, directly use the K-Factor. This approach is effective for materials like copper, where keeping a consistent thickness and bend angle allows us to rely on a fixed K-Factor value. For example, if we’re bending copper with a ¼” thickness with the same bend angle, the K-Factor remains constant, ensuring high accuracy for all similar projects.

Your Trusted Supplier for Formed Metal Components

Ameritex combines expert knowledge in custom metal fabrication with advanced equipment to provide high-quality results for every project. Our team has extensive experience in metal forming, cutting, welding, and finishing, making us a reliable partner for complex and precise metal components. Whatever your project’s requirements, we’re here to meet your specifications with top-tier expertise and the latest in fabrication technology.

Contact us today to discuss your project or request a quote. Ameritex is committed to delivering quality, consistency, and precision in every part we produce.