Your Guide to Common Manufacturing Metals and How Ameritex Brings Your Ideas to Life

At Ameritex Machine & Fabrication, we specialize in bringing innovative ideas to life using a variety of manufacturing metals. Whether you’re developing a new product, scaling a business, or simply exploring fabrication possibilities, choosing the right material is critical.

That’s why our team of experts are here to guide you every step of the way, from initial design to final assembly. Our focus on materials like aluminum, carbon steel, galvanized steel, stainless steel, super duplex stainless steel, chromoly, titanium, nickel, copper, and brass ensures your project gets the strength, precision, and finish it deserves.

Understanding the Benefits of Common Fabrication Metals

Aluminum: Lightweight Strength for Limitless Possibilities

Powder coated aluminum enclosure

- Tensile Strength: 90–570 MPa

- Melting Point: 660°C (1220°F)

Aluminum is widely used because it is lightweight, corrosion-resistant, and highly workable. It is perfect for applications where weight matters—such as switchgear enclosures, automotive parts, aerospace components, and consumer products. Its excellent conductivity and ease of laser cutting, bending, and welding make it a favorite for innovators seeking functional and efficient designs.

Learn more about aluminum in manufacturing (Aluminum.org)

Galvanized Steel: Affordable Protection Against the Elements

- Tensile Strength: Similar to base steel (varies)

- Melting Point: 1425–1540°C (2597–2800°F)

Galvanized steel is carbon steel coated with a layer of zinc to prevent rust and corrosion, making it ideal for outdoor structures, rooftop enclosures, structural support, and electrical housings. It is commonly used in building frames, guardrails, and HVAC systems.

Carbon Steel: Strong, Durable, and Cost-Effective

- Tensile Strength: 400–550 MPa

- Melting Point: 1425–1540°C (2597–2800°F)

Welder working on carbon steel parts.

Carbon steel is a top choice for structural applications because it offers high strength at an economical price. Common in construction, heavy machinery, and industrial frames, carbon steel is perfect for customers looking for durability and affordability. At Ameritex, we efficiently laser cut, bend, and weld carbon steel to bring even the most ambitious designs to life.

Stainless Steel: Beauty, Strength, and Corrosion Resistance

- Tensile Strength: 505–1275 MPa

- Melting Point: 1400–1530°C (2552–2786°F)

If you need a sleek, rust-resistant finish, stainless steel is your answer. It’s the go-to material for kitchen equipment, medical devices, and architectural structures. Stainless steel not only looks great but also stands the test of time. Ameritex excels in fabricating stainless steel products, offering flawless welding, bending, and powder coating in-house.

Super Duplex Stainless Steel: Superior Strength and Corrosion Resistance

- Tensile Strength: 700–1000 MPa

- Melting Point: 1350–1450°C (2462–2642°F)

With exceptional corrosion resistance and high strength, super duplex stainless steel is ideal for marine environments, oil & gas equipment, and chemical plants.

Chromoly: High Strength for Demanding Applications

- Tensile Strength: 560–880 MPa

- Melting Point: 1400–1450°C (2552–2642°F)

Chromoly (chrome-molybdenum steel) offers high strength with good ductility and weldability. It is commonly used in race car frames, aircraft structures, off-road vehicle roll cages, and bicycle frames for its outstanding strength-to-weight ratio.

Titanium: Strength, Lightness, and Biocompatibility

- Tensile Strength: 434–1530 MPa

- Melting Point: 1668°C (3034°F)

Titanium is corrosion-resistant, lightweight, and strong. It is preferred for aerospace components, medical implants, sports equipment, and marine applications due to its durability and resistance to extreme environments.

Nickel: Corrosion Resistance and Heat Tolerance

- Tensile Strength: 380–690 MPa

- Melting Point: 1455°C (2651°F)

Nickel and its alloys are known for their excellent resistance to heat, oxidation, and corrosion. They are widely used in power generation, chemical processing plants, jet engines, and marine environments.

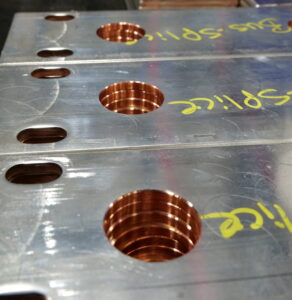

Copper: Power and Performance in Electrical Applications

Tin Plated Copper busbars used in Switchgear enclosure.

- Tensile Strength: 220 MPa

- Melting Point: 1083°C (1981°F)

With outstanding electrical and thermal conductivity, copper is essential for electrical wiring, busbars, plumbing systems, and heat exchangers. It is also used for decorative purposes due to its aesthetic appeal.

More on the importance of copper in manufacturing

Brass: Durable and Decorative

- Tensile Strength: 580 MPa

- Melting Point: 900–940°C (1652–1724°F)

Brass is an alloy of copper and zinc, prized for its machinability, corrosion resistance, and attractive gold-like appearance. It is used for plumbing fixtures, musical instruments, architectural elements, and industrial valves.

Surface Finishes and Treatments We Offer

To further enhance the performance and aesthetics of your parts, Ameritex offers a range of plating and treatment services, including:

- Zinc plating

- Tin plating

- Hot dip galvanizing

- Anodizing

- Passivating

- Chemical film treatment

These surface treatments improve corrosion resistance, enhance appearance, and provide additional protection for parts operating in harsh environments.

Why Ameritex Is the Perfect Partner for Your Innovation Journey

Choosing the right material is just the beginning. At Ameritex, we offer complete in-house manufacturing services to simplify your path to production:

- Precision laser cutting

- Expert press brake bending and forming

- Certified welding across multiple materials

- Complete assembly services

- Hardware insertion with a wide range of fasteners and hardware

- Premium powder coating and wet painting for durable, beautiful finishes

Our experienced engineers work closely with you to refine your ideas, optimize manufacturability, and deliver a production-ready product. Whether you’re crafting a prototype or ramping up to full production, we have the capabilities and passion to make it happen.

Bring Your Metal Fabrication Project to Life

If you’re looking for a trusted partner to help manufacture your idea with precision and care, look no further than Ameritex Machine & Fabrication. Let’s transform your concept into reality—with the right materials, the right team, and the right technology.

Ready to get started? Request a quote today!