Search our Knowledge Base

- All

- Announcements

- Custom Manufacturing

- Downloadable Resources

- Finishing

- Laser Welding

- Precision CNC Machining

- Precision Sheet Metal Fabrication

- Tube Laser Cutting

Copper Fabrication and Machining: 4 Reasons to Work with Ameritex

Copper fabrication and machining: yes, we do it! Ameritex has worked with copper for as far back as we can remember. But many customers don’t realize we provide copper fabrication and machining services until they take a shop tour and see the copper projects we’re working on. It’s time to demystify one of our best-kept secrets with a little show and tell. First, we’ll tell you what makes us a great copper machining and [...]

The Advantages of Rolla V Dies for Sheet Metal Bending

Ameritex invests in not only world-class equipment but also the best tooling to use that equipment to its fullest potential. Just recently, we acquired our first set of Rolla V dies for our press brakes. Although our selection is small for now, we intend to grow the range of die sizes we offer to meet customer demand. Punches and Dies: Understanding Press Brake Tooling Press brakes leverage two sets of tools—punches on [...]

Ameritex Partners with Lone Star College to Provide Free Manufacturing Training to Employees

Ameritex is excited to share that we are entering into an agreement with Lone Star College to develop a training curriculum and formal manufacturing training classes accessible to all our employees. This partnership will give employees the opportunity to escape the hustle and bustle of our precision sheet metal fabrication shop and receive thorough training at our neighboring Lone Star campus here in Conroe, Texas. When approved, this program will offer free training [...]

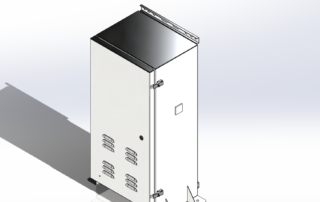

6 Considerations for Sound Attenuated Enclosures

Generators, pumps, and other industrial applications involving a large engine share one notable commonality: they are loud. Products that operate for extended periods at over 70 decibels often require a sound attenuated enclosure, which not only protects equipment but also shields the surrounding environment from harmful sound waves. Ameritex supports customers who provide “engineered to order” products to their end user with project based orders from quantity of one to several hundred enclosures. These [...]

Pipe and Tube Bending Services at Ameritex

“You guys have a tube bender?” “What size tubes can you bend?” These are common questions we receive from customers during shop tours, and we understand why. Tube and pipe bending are specialized capabilities that most sheet metal shops outsource. And to be fair, we don’t exactly advertise these capabilities to the same extent as our other metal fabrication services. But when our customers talk, we listen, and we’ve heard loud and clear that [...]

Leveling up Our Automated Deburring Capabilities

Ameritex is known for manufacturing custom fabrications that are true works of art, and one post-processing operation that helps us achieve this goal is deburring. Deburring is the process of removing sharp edges and slag (i.e., molten material that builds up and hardens on workpieces) that result from laser cutting. This step serves a couple of primary purposes in precision sheet metal fabrication: Deburring prepares parts for painting or powder coating. Wet paint and [...]

Blog Roundup: Don’t Miss These Blogs on Designing for Metal Fabrication Services

It’s hard to believe we’ve been blogging regularly for nearly two years now! We love using this space to keep customers informed about shop updates and Design for Manufacturing (DFM) tips that can save them time and money. Today, we’re rounding up seven can’t-miss blogs from 2022 on designing for sheet metal fabrication services. 1. What Is a Manufacturable Model and Why Is It Important for Metal Fabrication Services? 3D models play a critical [...]

Ameritex Is Now ISO Certified!

Customers seeking our sheet metal fabrication services asked for it. . . and we listened! After years of proudly maintaining compliance with ISO (International Organization for Standardization) standards at our Texas shop, Ameritex is pleased to announce that we are now officially ISO 9001:2015 certified! What It Means to Be ISO 9001:2015 Certified ISO 9001:2015 certification assures customers that a company has defined and follows an effective quality management system and can reliably provide [...]

Introducing Fast Lane Parts at Ameritex

Need your custom fabrications faster than ever before? As part of our commitment to getting customers their orders in record time, Ameritex is excited to announce a new service we’re calling Fast Lane Parts. After working with our partners at BeehiveFund to build out this offering so that we can reduce lead times on low-volume, low-complexity sheet metal parts. We currently offer a 3-7 day standard lead time for all Fast Lane Parts projects, [...]

What Is a Manufacturable Model and Why Is It Important for Metal Fabrication Services?

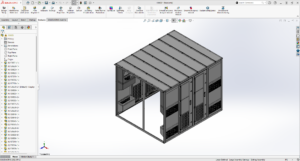

3D models play a critical role in most manufacturing processes. Customers use 3D models to visualize a product before it becomes tangible and engineer load calculations to prove a product will meet specific design criteria—to name a couple of common use cases. Sheet metal fabricators rely on 3D models for different but equally important reasons. A big one is programming machines to create customers’ parts as quickly and accurately as possible. For this reason, [...]