For high-precision sheet metal fabrication, choosing the right equipment for each job is essential. While fiber lasers are powerful and precise, a punch press offers unique capabilities that can make it the preferred option for certain applications. At Ameritex Machine & Fabrication, our LVD PX-1530 punch press is an integral part of our operation, allowing us to handle complex custom fabrications with speed and accuracy. This post explores the versatility of punch presses and highlights why the LVD PX-1530 is a standout in our equipment lineup.

What is a Punch Press?

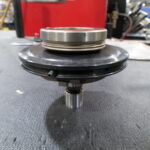

At Ameritex, the punch press is the heartbeat of our shop. A punch press is a versatile machine that cuts, shears, and forms sheet metal parts using a punch and die. Unlike laser cutters that use high-energy light to cut, the punch press exerts mechanical force, punching through the metal with impressive power. By adjusting the clearance between the punch and die to fit the material type and thickness, we achieve clean, precise cuts.

Punch presses can do much more than simple cutting. With specialized tooling, they can perform a variety of forming tasks, such as:

- Creating Louvers: Punch presses can produce louvers, which are vent-like structures that improve ventilation. These are especially useful in custom metal enclosures and other applications that require air circulation.

- Adding Protrusions: For applications where threads or attachments are needed, the punch press can create protrusions, effectively increasing the thickness of the material. This is beneficial for parts that require additional strength or threads.

- Inserting Knockouts: Punch presses can also add knockouts, which are pre-scored sections of the metal that end-users can later remove for additional access, commonly seen in electrical enclosures.

This versatility makes the punch press invaluable for applications that require more than simple cutting. It’s this combination of power and flexibility that keeps it at the core of our custom metal fabrication capabilities.

Punch Press vs. Fiber Laser

When it comes to choosing between a punch press and a fiber laser cutter, the decision depends on the specific requirements of the project. Each has strengths that make it ideal for different tasks:

- Efficiency with Patterns: For parts that require a pattern of holes, such as ventilation openings, the punch press can outperform a fiber laser. Custom tooling allows the punch press to create multiple holes in one stroke, drastically reducing processing time. What might take a fiber laser an hour could take the punch press only 15 minutes.

- Precision in Long Cuts: Fiber lasers excel in making long, continuous cuts, making them ideal for intricate designs and parts with extensive linear cuts. However, the punch press is often the better choice for projects that involve more complex shapes or features, where multiple shorter cuts and forms are required.

- Reduced Post-Processing: A punch press typically requires less post-processing than a laser, which can be an important factor in sheet metal finishing and cost efficiency. Punch-formed parts tend to have cleaner edges, reducing the need for additional smoothing or finishing steps.

- Custom Tooling Costs vs. Time Savings: While custom punch tooling involves an initial investment, this cost can be offset by the time savings on large production runs. For example, creating multiple identical holes across a large number of parts is much faster with a custom punch tool than with a laser. In situations where efficiency and high production volumes are priorities, the punch press is often the preferred choice.

The choice between punch pressing and fiber laser cutting ultimately depends on factors like design complexity, quantity, and budget. By evaluating these considerations, we select the best tool to ensure optimal results for each project.

The LVD STRIPPIT PX-1530

The LVD STRIPPIT PX-1530

Ameritex is proud to utilize the LVD PX-1530, one of the most advanced turret punches available. This machine brings a host of features that make it a standout for precision sheet metal fabrication:

- High Turret Clearance: With a 3” turret height, the LVD PX-1530 provides ample clearance for special tooling, allowing us to take on a wider range of forming tasks without risk of obstruction. This feature is particularly useful for creating protrusions, louvers, and other specialized features.

- Fully Indexable Pockets: All 20 pockets on the turret are indexable, meaning that tooling can be quickly swapped and adjusted for different tasks. This feature allows our team to efficiently switch between various tools and configurations, enhancing our flexibility and speed on the shop floor.

- User-Friendly Control Software: The LVD PX-1530’s software interface is intuitive and easy to use, enabling our operators to make quick adjustments and monitor production in real time. This feature minimizes downtime and helps ensure the highest quality on every job.

The LVD PX-1530 punch press plays a vital role in our facility. In fact, roughly 70-80% of the assemblies that come through our shop require processing on this machine. Its precision, speed, and flexibility allow us to consistently deliver high-quality parts that meet the exact specifications of each project. Whether you need metal fabrication services for a single prototype or a high-volume production run, our team has the tools and expertise to deliver outstanding results.

Experience Ameritex’s Advanced Metal Fabrication

At Ameritex, we’re committed to using the most advanced fabrication technology available. With decades of experience and a lineup of cutting-edge equipment (pun intended)—including our LVD PX-1530 punch press and LVD Phoenix FL-4020 fiber laser cutting machine—we offer quick turnaround times and unparalleled precision on every project. From forming to sheet metal assembly, we are equipped to handle all aspects of custom metal fabrication.

If you have a project that requires precise, efficient sheet metal cutting or forming, request a quote today. Ameritex has the expertise and state-of-the-art equipment to bring your designs to life with accuracy and speed.