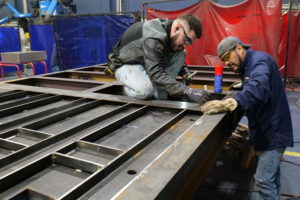

Ameritex Machine & fabrication specializes in the design and fabrication of custom skids (and other large structural fabrications) that meet the exact specifications of our customers. Whether you have detailed CAD drawings, a photo of a previous skid you’d like to replicate, or just a general idea of what you need, our team is ready to bring your vision to life. With decades of experience and a commitment to precision, Ameritex ensures that every custom skid is built to perform reliably, no matter the application or environment.

How Are Skids Constructed?

How Are Skids Constructed?

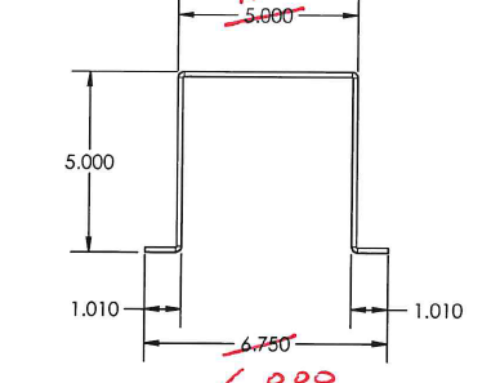

The construction of skids begins with a robust framework, typically made from structural steel members such as C channels, I beams, or L angles. These components form the skeleton of the skid, providing strength and stability to handle heavy loads and demanding environments. On top of the framework, one or more sheet metal plates are added to create a solid platform surface. Depending on customer requirements, these plates may be stitch-welded to the frame or designed to be removable for added flexibility.

Material Choices

Most skids are fabricated from ASTM A36 steel, a versatile carbon steel commonly used in industrial applications. In some cases, customers request a full stainless steel skid for environments with extreme exposure to moisture or chemicals.

Hardware Specifications

Hardware choices also depend on the skid’s intended use and environment. Options include stainless steel and hot-dip galvanized hardware to ensure longevity and performance. By selecting the right combination of materials and construction techniques, Ameritex delivers skids that meet the highest standards of durability and reliability.

Design Considerations for Custom Skid Fabrication

Custom skid fabrication requires careful consideration of several critical factors. At Ameritex, we take a consultative approach to ensure that every detail is accounted for, from structural integrity to environmental suitability.

Environmental Conditions and Load Requirements

One of the first design considerations is the environment where the skid will be used. Skids exposed to harsh outdoor conditions may require specialized coatings or materials to prevent corrosion. Additionally, the skid must be designed to withstand the loads it will bear. Customers often provide load requirements, such as a maximum weight capacity of 1,500 pounds. For added assurance, we can collaborate with professional engineers (PEs) to validate the design and provide signed-off drawings that certify the skid’s load-bearing capabilities.

Precision and Fit

Precision is crucial in custom skid fabrication, especially when mounting equipment that requires exact alignment. For example, motors or pumps often need to be positioned within tight tolerances to ensure proper operation. Our team’s deep expertise allows us to compensate for material deflection and other variances. For instance, I-beams can exhibit deflection ranging from 1/16” to nearly 3/8” from the web to the top of the beam. By accounting for these deviations during fabrication, we ensure a perfect fit and seamless assembly.

Custom Features and Flexibility

We understand that no two skids are alike. Customers may require unique features such as specific hardware placements, removable plates, or specialized coatings. Our flexible design process allows us to incorporate these customizations efficiently, delivering a skid tailored to the exact needs of the project.

Custom Skids, Built to Your Exact Specifications

At Ameritex, we pride ourselves on our ability to turn our customers’ ideas into reality. The key to a successful project lies in clear communication and collaboration. We work closely with our clients to understand their requirements and provide detailed feedback throughout the design process. From initial concepts to final fabrication, we ensure that every skid is built to achieve its intended purpose.

The more details you can provide about your project, the better we can tailor the design to meet your needs. Whether you’re specifying materials, hardware, or unique design features, our team is here to guide you every step of the way. With Ameritex, you can trust that your custom skid will be fabricated to the highest standards of quality and precision.

Ready to start your next custom metal fabrication project? Contact us today to learn how Ameritex can deliver the custom skids you need to elevate your operations.