Most believe that excellence is a destination, not a journey. We think the opposite, because we know that excellence is a lifelong journey and a principle that we follow every single day.

Our commitment to constant improvement is woven into every aspect of our operations. By refining our processes, expanding our knowledge, and leveraging advanced technologies we reduce downtime, enhance employee safety, and deliver high-quality products to our customers.

Below, we’ll walk you through how Ameritex Machine & Fabrication stays ahead in the custom metal manufacturing industry by improving work instructions, enhancing maintenance procedures for our machines, and developing robust internal educational content for our team.

New Process for Shop Floor Work Instructions

Being a job shop by nature every project on our shop floor is an opportunity to learn, adapt, and improve. To ensure precision and repeatability, we’ve implemented a structured system to document and address issues encountered during production runs.

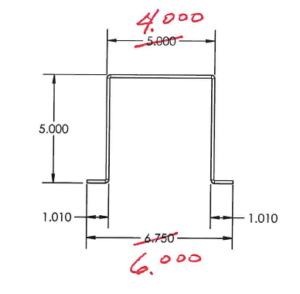

For instance, when running a tube laser cutting operation, we sometimes encounter prints that lack a view showing the correct position of the holes. Without this information, verifying the part during inspection becomes challenging, slowing down fabrication and increasing costs. Similarly, in our fabrication area, unclear welding symbols or sequences in prints can require additional attention.

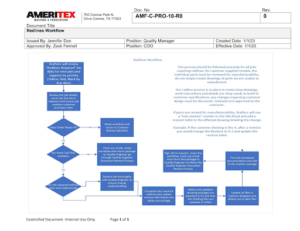

To solve these issues, we redline each drawing or specification that requires clarification. This ensures that the findings from the first run of parts are applied to all subsequent runs. Beyond digital documentation, we also use physical sheets featuring photos of known issues. These sheets are kept on the shop floor, and operators are required to review and sign off on them before starting work.

This meticulous approach ensures clarity for operators and leads to higher-quality outcomes for our customers.

Improved Autonomous Maintenance for Our Machines

Minimizing downtime is critical in manufacturing, and as such we’ve implemented proactive solutions to keep our machines running smoothly.

One example involves the conveyor system that works alongside our sheet lasers to remove scrap parts automatically during cutting. Over time, we noticed these conveyors could get clogged, causing delays and inefficiencies. To address this, we implemented a simple but effective maintenance procedure: operators now lift the safety door in a specific way (only when the laser is powered down) to clean out scrap metal.

This change, though seemingly small, has significantly reduced downtime and material waste while improving overall operational efficiency. By continually monitoring machine performance and finding ways to streamline maintenance, we ensure our equipment delivers consistent results for our customers.

Continuing Education and Training

At Ameritex, we understand that investing in our team is one of the most impactful ways to improve our processes and outcomes. To this end, we’ve hired a learning specialist to create comprehensive training materials for our employees.

Ameritex’s workflows for determining Redlining

Our internal educational content includes videos, tutorials, and courses designed to onboard new personnel and enhance the skills of existing team members. These resources cover essential topics like operating lasers, press brakes, and punch presses, starting with introductory courses and expanding into intermediate and advanced levels.

For example, someone new to our team can begin with foundational knowledge and progress to mastering complex machine operations. This ensures consistency, fosters a culture of learning, and empowers our team to perform at their best.

Leading the Industry with Continuous Improvement

Our dedication to process improvement isn’t just about optimizing operations—it’s about exceeding expectations. From refining shop floor practices to implementing smarter maintenance routines and empowering our team with knowledge, every step we take is aimed at delivering exceptional value to our customers.

As we move forward, our focus remains steadfast: combining precision, innovation, and a commitment to excellence to set the standard in custom metal fabrication. Let us show you how each improvement can make your next project seamless and successful.

Ready to see the Ameritex difference? Contact us today to discuss your next project or request a quote.