Our mission to combine expertise and technology to deliver unmatched precision and quality in every project. Recently, our team deepened its mastery of tube laser cutting by attending advanced training at the headquarters of BLM Group, the manufacturer of our state-of-the-art LT8.20 tube laser cutting machine. This intensive learning experience revealed exciting ways to optimize programming and maximize the capabilities of this advanced machine. The result? Greater efficiency, superior quality, and innovative solutions for our customers.

Here are five ways of how we leverage the full potential of our tube laser cutter to ensure your custom fabrications are in expert hands.

Example 1: Band Saw vs. Tube Laser

Traditional methods like band saw cutting have long been staples of fabrication, but the LT8.20 tube laser transforms what’s possible.

Traditional methods like band saw cutting have long been staples of fabrication, but the LT8.20 tube laser transforms what’s possible.

For structural parts requiring straight cuts, the tube laser performs these operations far faster than a band saw, while eliminating the wear and tear of saw blades. It doesn’t stop at straight cuts. With the tube laser, we can create complex features like chamfered or curved holes directly in a piece of pipe. For instance, we can cut a slot, insert another piece of material, and prepare it for welding—all in one seamless process.

In contrast, a band saw would require multiple steps, including cutting, drilling, and additional prep work. By streamlining operations with the tube laser, we not only save time but also deliver precision that manual processes simply can’t match.

Example 2: Many Features in a Single Tube

In many projects, a single tube may require multiple distinct features. For example, a square tube might need two large openings on opposite sides, along with smaller features elsewhere.

Our tube laser allows us to strategically sequence these cuts. First, we cut one feature, move the tube forward, and cut the next. Then, we return to the initial side to complete the remaining features. This approach minimizes heat buildup, prevents material warping, and ensures clean, precise cuts every time.

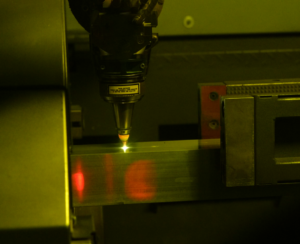

Example 3: Enable Active Tilt

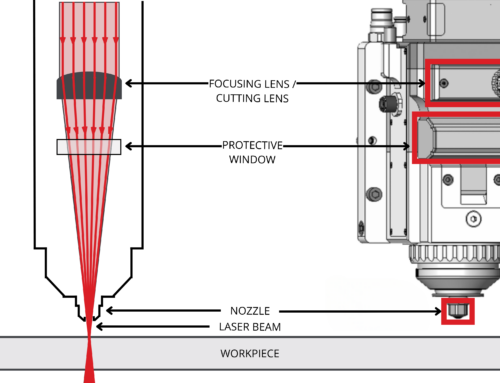

One standout feature of the LT8.20 is its ability to tilt the cutting head by more than 15 degrees while simultaneously rotating the workpiece. This capability enables us to produce features that would be impossible to cut on less sophisticated machines.

One standout feature of the LT8.20 is its ability to tilt the cutting head by more than 15 degrees while simultaneously rotating the workpiece. This capability enables us to produce features that would be impossible to cut on less sophisticated machines.

Active tilt technology optimizes the cutting process for complex geometries, such as angled cuts and intricate beveled edges. This level of precision ensures that your components are ready for assembly, reducing the need for secondary processing.

Example 4: Optimized End Piece Cuts

Creating clean and functional end cuts is crucial for structural assemblies like handrails or custom frames. The tube laser excels at producing curved cuts that fit together like puzzle pieces.

This approach eliminates the need for cumbersome fixtures and clamps during welding. By enhancing the fit and finish of these joints, we can accelerate assembly times and improve the overall structural integrity of the final product.

Example 5: Automatically Sorting Parts and Scrap

Efficiency extends beyond cutting. Our LT8.20 is equipped with advanced conveyors that separate short parts from scrap material automatically.

Even when parts and scrap are similar in size, the machine’s programming ensures accurate sorting. This feature not only reduces manual labor but also keeps operations running smoothly, allowing us to maintain fast turnaround times while minimizing waste.

Why Choose Ameritex for Tube Laser Cutting?

Optimizing our tube laser cutting services is just one example of how Ameritex applies its deep expertise in custom metal fabrication to deliver outstanding results. By continuously refining our processes and staying at the forefront of fabrication technology, we ensure that your projects are handled with the utmost care and precision.

Whether you’re designing components with intricate features or need efficient production of structural assemblies, our team is ready to turn your vision into reality.

Ready to take your project to the next level? Contact us today to learn more about our capabilities, or request a quote to see how Ameritex can bring precision and efficiency to your next project.